UV printing is currently the cutting-edge solution in the field of large format digital printing on all kinds of flat materials, including on PVC.

The print is made directly on a rigid material using inks that are hardened on the substrate surface using UV lamps. Thanks to that, all kinds of works related to fixing the prints are eliminated.

White ink enables making a selective sub-print on a substrate of any colour. By using white ink, we can print on transparent media using the overprinting technique.

UV printing enables achieving nearly photographic quality of print. It also enables making a direct, well-adhering print on any substrate. The prints can be employed indoors. At the same time, they are resistant to water, humidity and sun and can be used outdoors as well. Prints on PVC and other substrates do not require drying and can be processed further, cut and packed right after printing.

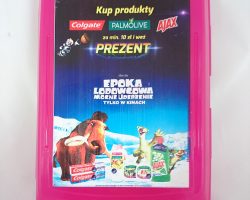

The main fields of application of UV printing is advertising and decoration. It constitutes an alternative to screen printing and fixing printed foil to surfaces using adhesives.

The application of UV printing technology enables direct:

- printing on carton board and cardboard

- printing on PVC

- printing on sheet metal

- printing on woods: planks, plywood, furniture boards and doors

- printing on glass: prints on glass panes, mirrors and glass elements

- printing on ceramic tiles

- printing on blinds and shades

- printing on other flat materials